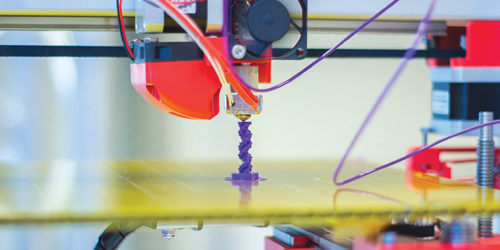

The manufacturing industry in the UK, and indeed the world, is facing challenges and opportunities that come once in a lifetime. 3D printing, which has evolved over the last 30 years, is now reaching the tipping point where it is entering the mainstream.

We conducted one-to-one research with companies working with the technology - using 3D printing to produce prototypes as well as finished parts, and those developing software relevant to 3D printing, design protection and data logistics. The results were fascinating.

We found that the major motivations for companies to use 3D printing fell into four main categories:

1. Supply chain disruption: It allows companies to take back control of their supply chain by producing their own parts.

2. Mass customisation: Being able to quickly customise products without the need for expensive and dedicated tools.

3. Reverse engineering: Not only does 3D printing allow the design and creation of customised products, it allows models to be created from products.

4. Making the impossible possible: It allows the creation of products that other manufacturing methods would not have allowed.

However, while new technology allows innovation, it also brings threats which businesses must address. For every instance where companies save money and resources by reducing manufacturing waste or transport costs, there is the danger of intellectual property (IP) and competitive advantage being undermined.

One of the most attractive attributes of 3D printing is that a manufacturing business needs only to move data to the printer, wherever it’s situated, to enable local manufacturing. This effectively eliminates the transport of goods and the need to have some degree of inventory in their distributed manufacturing locations. However, whoever holds the data also holds the key to the castle.

Our research uncovered an instance of valuable IP being shared, without permission, with a Chinese sub-contractor. Bearing in mind that this UK company’s biggest competitor is in China and the part was rich in IP - being part of a new product range - the company was not impressed. To prevent the situation from happening again, they decided to expand their own 3D printing capacity by buying a higher resolution machine. In fact, several of the companies we visited had gone through a number of different 3D printing machines, and could see themselves investing in new machines on an ever more regular basis.

To help companies make the most of 3D printing, while still keeping IP secure, we’ve put together the following top ten tips for businesses.

Ten top tips for making the most of 3D printing

1. Evaluate the strategic benefits that 3D printing could bring to your business through increased agility and reduced product development time scales.

2. Secure your data both internally and externally. If you need to share designs with third parties, use geometrical models viewed through web based viewers. This means that you can avoid sending sensitive design files which can be rapidly disseminated and easily exploited through 3D printing.

3. For added security, invest in your own 3D printing capability to print prototype designs in-house.

4. Technology is constantly changing and advancements may overtake your current development and protection strategies. Keep up-to-date with changes in the industry to avoid this happening to you.

5. Set up as many barriers as possible to prevent the copying of your products. Remember to follow tried and trusted strategies to protect IP, such as design rights, patents and trade marks.

6. Place greater emphasis on determining which parts of your products may need their own individual protection.

7. If you are allowing customers or suppliers to 3D print finished parts of your own design, consider posting them on a site where distribution is controlled. You must have strict contractual terms agreed between you and the 3D printing bureau to give you added protection in case of any lost data, IP infringement or other legal liability.

8. If making production parts, ensure that you have appropriate control of processes within your organisation and with any sub-contractors you may use.

9. When making production parts, look to protect the process, not just the shape of the parts. Get advice to ensure the most important aspects of your products are properly protected.

10. As well as protecting the process used to create products, think about protecting the materials being used and how important they are. This may be through IP or an exclusive contractual agreement with the supplier.

To download a full copy of the report, please visit the news and resources section of our website: www.dmhstallard.com

For more information or a free, no obligation chat with one of our experienced technology lawyers, please call Robert Ganpatsingh on 01273 744213 or email robert.ganpatsingh@dmhstallard.com